PubNub Insights for Industry 4.0 Predictive Maintenance

How to use PubNub Insights for Industry 4.0 Predictive Maintenance

Industry 4.0 is revolutionizing the manufacturing landscape by leveraging data analytics, artificial intelligence, and automation to optimize production processes and drive operational efficiency. Predictive maintenance is a powerful application of Industry 4.0, enabling businesses to anticipate and prevent equipment failure by monitoring and analyzing machine data in real-time.

PubNub Insights is a robust and user-friendly analytics tool that provides businesses with comprehensive insights into their app's performance and user behavior.

This blog post will explore various ways Insights can help businesses understand equipment health, identify potential failure points, and optimize maintenance schedules for peak performance. So, let's dive in and explore the potential of PubNub Insights for Industry 4.0 predictive maintenance applications.

Identifying Equipment Usage Trends

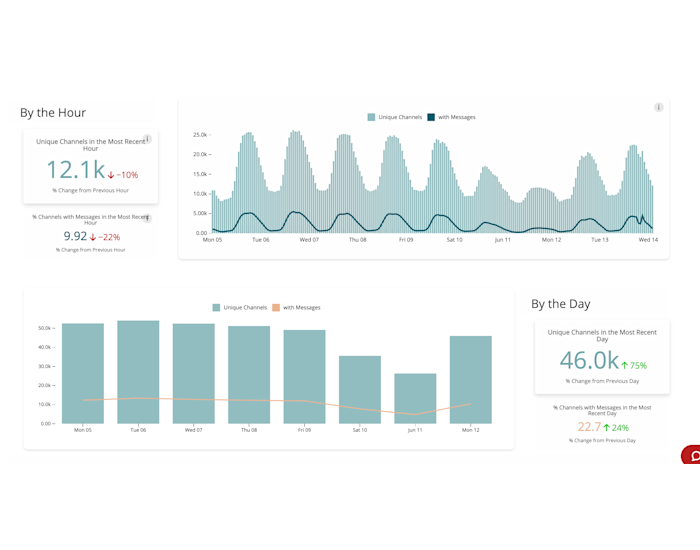

Using PubNub Insights to monitor trends and understand equipment usage patterns across various time periods and geographical locations, organizations can efficiently allocate resources to accommodate peak usage periods, avoid overloading, and prevent unexpected downtime.

By going to the Snapshot tab in PubNub Insights, businesses can view location metrics to compare equipment usage data across different geographical areas and time periods. Comparing equipment usage by location helps decision-makers identify regions with higher demand, allowing them to allocate resources accordingly and optimize maintenance schedules for enhanced performance.

You can also look more closely at location-based message activity by referring to the Messages tab. You can make assumptions on peak usage periods for specific equipment or monitoring channels, revealing patterns or trends. Understanding when particular assets experience increased usage helps set up optimized maintenance schedules that minimize disruptions to daily operations.

Detecting Anomalies in Equipment Performance

Anomaly detection is an essential aspect of Industry 4.0 predictive maintenance applications, as it allows businesses to identify potential failures before they escalate into costly operational issues. PubNub Insights provides the tools to monitor equipment performance and detect anomalies, empowering businesses to maintain optimal functionality and reduce downtime.

Assessing Channel Activities

By examining the Channels Dashboard within Insights, technical and product teams can gain valuable insights into the activities across different equipment channels. This information helps teams promptly identify and address performance irregularities, ensuring smooth equipment operation and preventing potential failures.

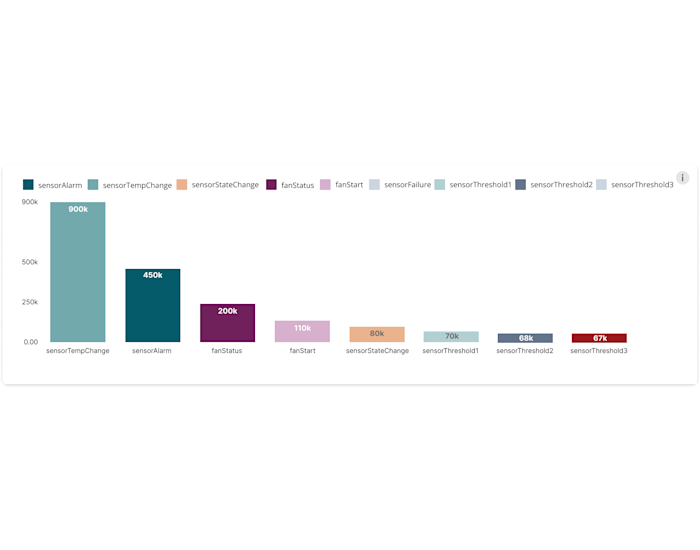

Investigating Top 20 Channels

The Top 20 Channels section within the Channel tab allows you to analyze the predominant utilization of specific equipment or features. By identifying irregularities or unexpected spikes in usage trends, you can quickly react and address potential equipment issues that might impact overall performance.

Monitoring Message Sources

Businesses can view the source of messages related to equipment performance using the Snapshot and Messages tabs. Messages being published from a single central location rather than multiple client-side sources could signify an unanticipated load on specific equipment/location or potential equipment failure. By monitoring and analyzing these messages, businesses can proactively address these issues and prevent expensive downtime.

Detecting anomalies and promptly resolving equipment issues is crucial in Industry 4.0 predictive maintenance applications. By leveraging Insights, businesses can effectively anticipate and prevent potential failures, ensuring seamless equipment operation and maximizing productivity.

Optimizing Resources and Channel Management

Resource optimization is crucial for achieving operational efficiency in Industry 4.0 predictive maintenance applications. PubNub Insights allows businesses to identify highly active and less active channels, enabling better resource allocation and channel management to minimize costs and maximize equipment performance.

Identifying Most Active Channels

By navigating to the Channels tab in Insights, businesses can gain insights into the activity levels of various equipment channels. The Top 20 Channels section helps identify the most used equipment or features, allowing organizations to prioritize resources while maintaining peak performance. If you want to see more than your top 20 for analysis, you can export the Top 1000 through the Expanded Data Download feature.

Retiring Less Active Channels

Less active channels, on the other hand, may represent equipment that is no longer vital to the operational objectives. By identifying and retiring these channels, businesses can reallocate resources to more critical equipment and enhance operational efficiency.

Revisiting Implementation and Architecture

Businesses can utilize the data provided in Insights to assess if their current architecture matches their Industry 4.0 predictive maintenance application requirements. This evaluation helps to optimize resource allocation and address potential discrepancies in channel management, ensuring that resources are effectively utilized to meet the changing operational demands.

Resource optimization and channel management are vital for maximizing productivity and operational efficiency in Industry 4.0 predictive maintenance applications.

Driving Long-term Success in Industry 4.0 with PubNub Insights

Comprehensive Analytics

PubNub Insights provides comprehensive analytics capabilities, enabling businesses to monitor trends, detect anomalies, and understand equipment usage patterns. These insights empower organizations to make evidence-based decisions that enhance equipment performance and reduce maintenance costs.

Continuous Improvement

As user preferences and industry requirements evolve, businesses must continually assess and adapt their predictive maintenance applications to stay competitive. By actively tracking performance data and user interactions through PubNub Insights, organizations can identify areas for improvement and optimize their applications to cater to the changing demands.

Seamless Integration

PubNub Insights offers a user-friendly interface requiring zero code setup, making integrating with existing Industry 4.0 predictive maintenance applications easy. Businesses can quickly begin monitoring their equipment and users without extensive development efforts, thereby accelerating data-driven decision-making. Embrace the potential of PubNub Insights and drive long-term success in the dynamic world of Industry 4.0.